Several thousand blow molded products are produced ever […]

Several thousand blow molded products are produced every hour. But, there are also many cases where the product is defective. This can lead to waste of raw materials. Therefore, manufacturers should focus on safety and protection of the workers and the supply network.

The blow molding machine market is segmented into type, application, and region. The Asia-Pacific region holds the largest share of the global blow molding machine market. The Asia-Pacific region is expected to maintain its dominance in the future. The main reason for its rapid growth is the increase in manufacturing industry.

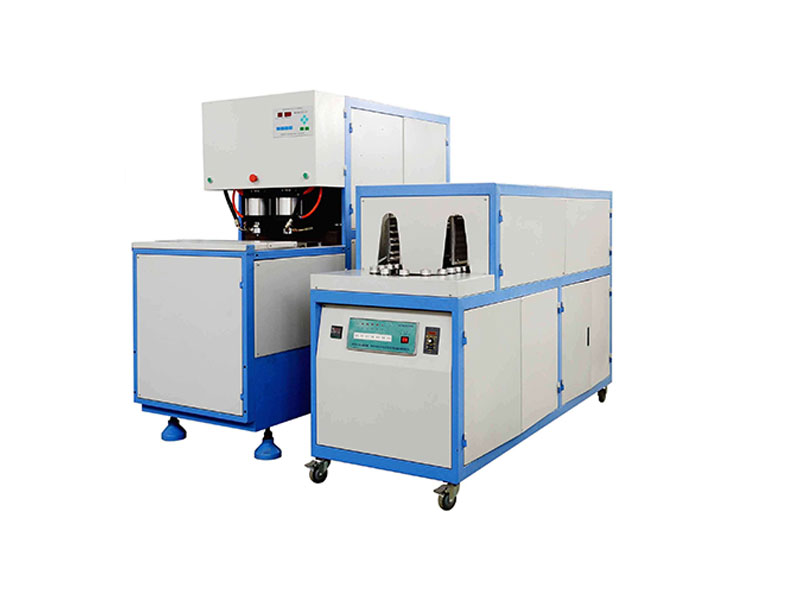

There are two types of blow molding machines: injection and extrusion. Injection blow molding is a process that produces hollow plastic bottles and containers from a molten polymer. Acrylonitrile Butadiene Styrene (ABS) is one of the common types of plastics used in this process. It has good hardness and rigidity.

Injection blow molding is also used to make hollow glass objects. This process is highly popular all over the world. It has the capacity to meet exacting standards on tolerance, volume, and quality.

After the initial heating, a thick tube of molten polymer is pushed into an orifice in the blow mold. This melted plastic is then pressed against the inner wall of the mold. The heat causes the plastic to swell and adhere. After cooling, the cooled plastic is ejected from the mold.

The blow moulding machine should be cleaned after the worksite. A safety door should be installed at the exit of the molding to prevent a person from entering the mold.